Mold Production

Mold Production

Unmanned Aerial Vehicles and their parts are commonly manufactured from composite materials. Methods such as wet lay-up, vacuum infusion, prepreg are used to produce with composite materials. In order to produce composite materials with these methods, we produce molds suitable for printing composite parts with different properties. When mold production is carried out, it is very important to ensure compliance with part geometry, smoothness and easy removal. The application to be selected from mold production methods should be determined depending on the requirements of the project, materials and production process.

The mold production methods that are widely used in the field of aviation and that we produce are mainly epoxy mold, polyester mold, aluminum mold and MDF coated mold. We determine the option for your needs together and continue the process with mold design.

We check the suitability of your UAV or part design for production and complete the mold design. The designed molds are prepared for production and precisely processed with CNC Router. We also produce the necessary alignment and joining apparatus for the mold. Mold life and cost vary according to mold options. At the same time, the precision in surface quality varies. You can examine mold production methods and processes to determine the most suitable mold options for you.

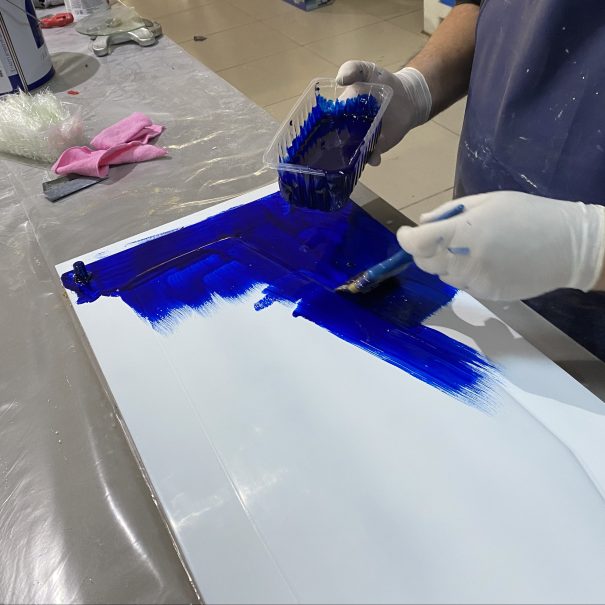

Polyester/Epoxy (Composite) Mold

Epoxy or Polyester resins are widely used materials for mold production. In this method, a male (positive) model of the desired part is first prepared. This model is precisely machined with a CNC router using wood material. Then the surface of the model is smoothed. Mold release material is applied to the model with a smooth surface and the resin is made ready for the casting stage. Depending on preference, epoxy or polyester resin material is applied on the model using felt. After the resin hardens, the mold is removed from the model and it is ready for use. This method provides ease and robustness in the production of parts with complex geometry.

Approximately 30-35 Unmanned Aerial Vehicles or parts can be easily produced with this method. Depending on the mold design, the mold production process takes approximately 2 to 5 weeks.

Aluminum Mold

Aluminum molds are a very good production method for its strength and excellent surface precision. In the aluminum mold production method, female models of the part to be produced are created. In addition, alignment pins and joining holes are determined within the mold design. The suitability of the model for the machining operation is checked and precisely machined using CNC Router. The surface of the machined model is smoothed with polishing application. After this process, the mold is ready for use.

This method is long-lasting and the surface precision is quite high. However, since the weight of the molds to be produced will be higher than other methods, it may cause difficulties in transportation and joining situations. In addition, the cost of mold production is higher than other methods. The production process takes approximately 2 to 5 weeks depending on the part design.

MDF Mold (Resin Coated)

MDF molds are a production method used in composite part production with fast production process and low cost features. The female mold design of the part to be molded is made. Then it is precisely processed with CNC Router. The surfaces of the processed wooden models are hardened with resin. Different chemical materials and paints are used for surface smoothness. The surface is polished by sanding and the mold is ready for production. This method is suitable for prototype production or small quantity composite production.

Approximately 4-5 sets of composite parts can be produced with this method. It stands out with its affordable mold production price and fast production process. However, surface quality and mold life are lower than other methods. The production process varies according to the part design and takes approximately 1 to 4 weeks.