UAV Design and Analysis

UAV Design and Analysis

Original UAV Design

We providefixed wing/multicopter/VTOL UAV design and analysis services for your needs . After a preliminary meeting with our team, we design an original unmanned aerial vehicle according to your requirements and the production method we will determine.

First, we start our work with the conceptual design phase. The wing profile is selected and the wing, tail and fuselage dimensioning phase is carried out as a result of the analysis. Then, flow analyses are performed in computer environment. Structural analysis, stability analysis, flight data analysis, engine thrust tests and power consumption tests are also carried out. The results of the analysis are reported in detail and you can easily proceed to the production planning phase.

Aircraft design is achieved through a series of stages, which you can examine in detail below. Each phase progresses using data and feedback from previous phases. Depending on the project requirements and complexity, the design and analysis process may involve more detail or require different approaches. As a result, we create a unique design.

Conceptual Design

Requirement Determination: The intended use, requirements and performance criteria of the UAVs are determined.

Configuration Options: Unmanned Aerial Vehicle’s general design concepts, dimensions, structural layout, wing and fuselage shapes, control mechanisms, propulsion and power systems, etc. are considered and selected.

Performance Estimates: Performance predictions of conceptual design options are made through aerodynamic analysis. Factors such as lift, drag, moment, range and flight time are evaluated.

Conceptual Design Selection: The most appropriate conceptual design is selected by considering performance, cost, manufacturability and other criteria.

Pre-Design

3D Modeling: The selected version from the conceptual design is created as a 3D CAD model.

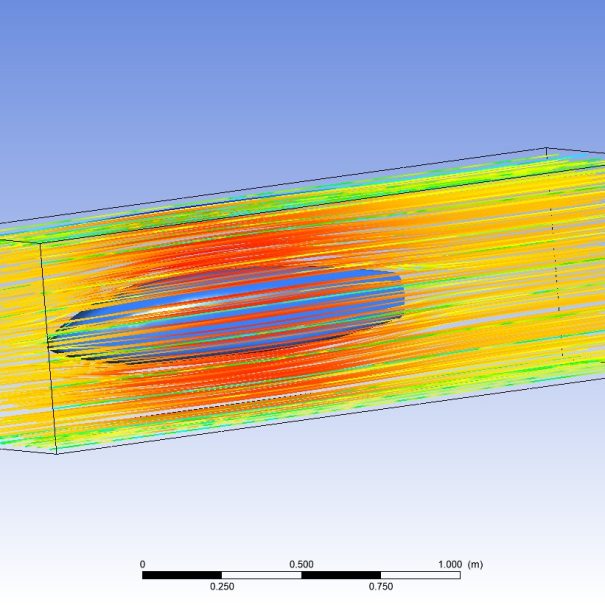

Aerodynamic Analysis: Various simulations and computer-aided analysis tools are used to analyze the aerodynamic performance of the UAV. These analyses evaluate factors such as lift, drag force, and stability by examining the effects of airflow on the UAV.

Propulsion and Power System: The propulsion system that the unmanned aerial vehicle will use is determined by selecting the motor, propeller, and ESC. A decision is made regarding the propulsion method (electric/combustion engine). Calculations are performed for the power system.

Control Systems and Electronics: The preliminary design of the UAV’s control systems and electronic connections is carried out.

Weight and Balance Analysis: The weight distribution and balance control of the UAV are analyzed.

Detailed Design

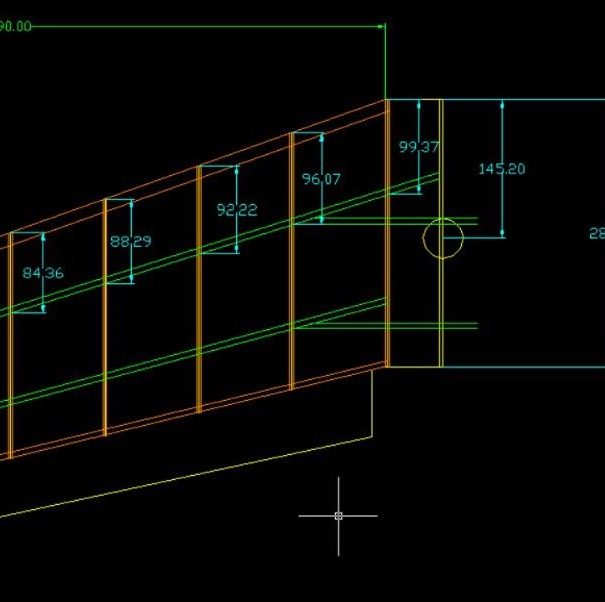

Detailed CAD Design: Detailed CAD modeling is performed for all components of the UAV, including the wings, fuselage, propeller, and control surfaces.

Material Selection and Structural Analysis: The materials to be used for the UAV’s structure are selected, and structural analyses are conducted.

Manufacturing Design: Design details for the UAV’s production, such as manufacturing plans, assembly instructions, and tolerances, are determined.

Electronics and Software Design: Work is carried out on the UAV’s electronic components and control software. Electronic materials are selected.

Detailed Aerodynamic Analysis: A detailed aerodynamic analysis of the UAV is performed. Performance results are evaluated and compared with the requirements. Performance parameters such as cruise speed, stall speed, maximum speed, required thrust power, flight time, moment coefficient, lift coefficient, drag coefficient, and stability are determined.

Production

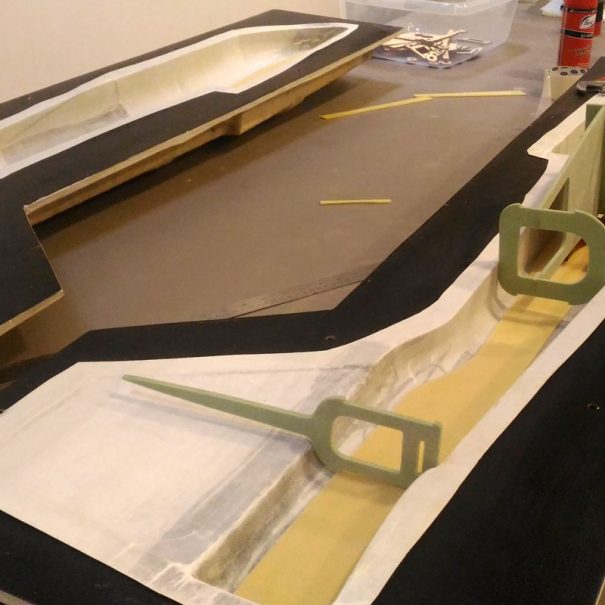

Prototype Production: Prototype production allows for testing the design under real-world conditions and making necessary improvements. A prototype is produced from detailed designs using materials such as wood, foam, or composite. During this phase, the structural components are manufactured, assembled, and made ready for testing.

Testing and Quality Control: The produced UAV prototype is evaluated through testing and quality control processes. This step is crucial for verifying the design and making improvements if needed.

Mold Production: After the prototype phase, material and production planning are conducted, followed by mold design and production. Molds can be made from epoxy, polyester, or aluminum materials.

Testing

Ground Tests: Ground tests of the UAV are conducted, including checks on control systems, motor thrust testing, motor performance testing, and evaluations of electronic components and software.

Flight Tests: The UAV undergoes real-world flight testing, where flight performance, maneuverability, range, altitude, and turn radius parameters are tested and documented.

Data Analysis and Improvement: Test results are analyzed, with flight logs and other data reviewed by our team of flight mechanics experts. A flight performance report is generated, identifying areas for improvement. Necessary corrections and enhancements are made.

After successfully passing the testing phases, the UAV enters the mass production process and is made available for use.

Completed Mini UAV Projects

3+

Multicopter

2

Fixed Wings

3+

VTOL